Titantrek creates travel gear that’s built to last, combining durable materials, precise manufacturing, and rigorous testing. Here’s what sets their products apart:

- Vacuum Compression System: Shrinks clothing volume by up to 50%, simplifying packing. Featured in the $199.00 Atlas Vault Backpack.

- Premium Materials: UV-resistant, weatherproof polymers protect against fading, moisture, and wear.

- Rigorous Testing: Products undergo compression, durability, and climate tests to ensure reliability.

- Thoughtful Design: Includes TSA-approved locks, padded straps, and anti-theft pockets for secure and comfortable travel.

Titantrek’s Southern Germany facility follows a 26-step production process, ensuring every product meets high-quality standards. Whether you’re packing bulky winter gear or heading on an outdoor adventure, their gear is designed to perform in all conditions.

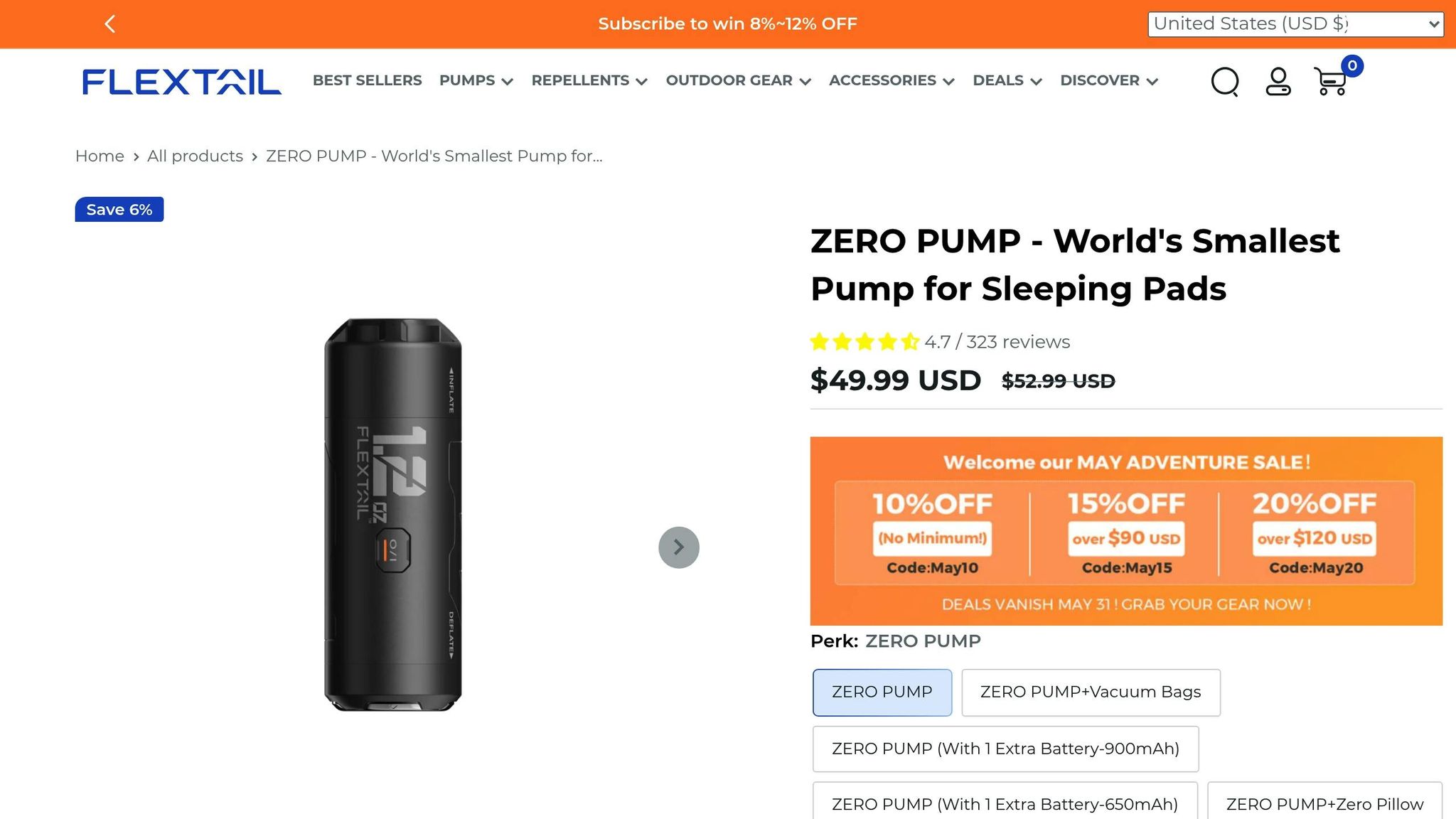

Vacuum Bags for Carry-on Travel, Game Changer or Gimick? (Tested Using the Flextail Zero Pump)

Premium Materials and Construction

Titantrek carefully chooses every component of the Atlas Vault Backpack to ensure it performs reliably, even under demanding travel conditions. Here's a closer look at the materials and construction features that set it apart.

Durable and Lightweight Polymers

The Atlas Vault Backpack is made from tough yet lightweight polymers. These materials are designed to handle the wear and tear of daily use while maintaining their integrity during vacuum compression.

Built for All Weather Conditions

Designed with outdoor adventures in mind, the backpack uses weather-resistant materials to protect your belongings. Its sturdy outer shell, combined with sealed construction elements, offers excellent defense against moisture while maintaining proper ventilation.

Reinforced Stitching and Structural Support

With advanced stitching techniques and reinforced support panels, the Atlas Vault evenly distributes weight. This thoughtful design ensures the backpack retains its shape and functionality, even after repeated compression cycles.

Manufacturing Standards

At Titantrek's cutting-edge facility in Southern Germany, every Atlas Vault Backpack goes through a meticulous 26-step production process designed to deliver unmatched durability and quality. This systematic approach ensures that each backpack meets the highest standards of craftsmanship and reliability.

Precision Assembly

Crafting an Atlas Vault Backpack involves assembling 145 carefully chosen components across 26 detailed steps. Many of these steps are performed by hand, ensuring precise alignment, secure connections, and long-lasting durability [2].

Quality Inspection

Throughout the production process, rigorous quality checks are conducted. These inspections focus on material strength, seam durability, and overall functionality, ensuring that every backpack upholds Titantrek's stringent quality benchmarks [2].

Production Tracking

Titantrek takes pride in sourcing materials from trusted regional suppliers. This ensures that only premium, thoroughly tested components are used in the manufacturing process [2].

"The only way to achieve the highest TITAN quality is to manufacture every suitcase ourselves in Germany" [2].

Product Testing Methods

At Titantrek's cutting-edge facility, every product is put through rigorous testing to replicate real-world travel conditions. These tests are designed to ensure that each item delivers the durability and performance adventurers rely on.

Compression Tests

The vacuum compression system is evaluated under simulated environmental changes and repeated compression cycles. This ensures the system performs reliably over time, even under demanding conditions.

Durability Tests

Titantrek products are subjected to a range of durability evaluations, including abrasion resistance, impact protection, zipper functionality, and strap strength. For example, the polycarbonate components, sourced from trusted partner Senoplast, are stress-tested to confirm they can handle tough travel scenarios.

| Test Type | Test Description | Acceptance Criteria |

|---|---|---|

| Abrasion Resistance | Simulates prolonged wear through extended cycles | No visible wear |

| Impact Protection | Drop and shock testing | No structural damage |

| Zipper Durability | Repeated opening and closing cycles | Smooth and reliable operation |

| Strap Strength | Assessed under heavy loads | Maintains integrity without deformation |

Climate Tests

To prepare for all kinds of adventures, products are tested in simulated environmental conditions. These tests expose items to extreme temperatures, high humidity, and heavy rainfall, ensuring they perform reliably no matter the weather. Insights from these evaluations directly inform ongoing improvements to the product line.

Titantrek's commitment to quality runs through every step of its production process. Testing protocols are designed to conserve resources while maintaining strict performance standards, ensuring products meet the high expectations of travelers everywhere.

sbb-itb-b1567d8

Travel-Focused Design

The Atlas Vault Backpack isn't just built to last - it's crafted to make traveling more comfortable, organized, and secure. Every detail is tailored to meet the needs of travelers who demand both functionality and reliability.

Comfort Features

For those long journeys, the Atlas Vault Backpack offers padded straps and a ventilated back panel, easing the strain on your shoulders and back. These thoughtful additions reduce fatigue, making it a breeze to carry your essentials, no matter how far you’re going.

Vacuum Compression System

Packing smart just got easier. With its built-in vacuum compression system, this backpack allows you to compress your belongings neatly and efficiently. The result? A compact, organized bag that doesn’t sacrifice its sturdy design.

Security Features

Travel worry-free with features like TSA-approved locks, waterproof materials, and discreet anti-theft pockets. These elements work together to keep your valuables safe while still allowing for quick and easy access when you need it most.

Product Development Process

Our product development process goes beyond just manufacturing and testing. It’s about perfecting every detail. By combining rigorous field testing with valuable customer feedback, we aim to ensure each product is built for durability and real-world functionality.

Expedition Testing

We push our gear to its limits by testing it in harsh, real-world conditions. This hands-on approach ensures that every material and component holds up under tough environments, meeting the high standards we set for reliability and performance.

Customer Input

Your feedback shapes our designs. Through surveys, testing programs, and direct conversations, we gather insights from customers to refine and improve our products. This collaboration helps us create gear that meets the evolving needs of modern travelers.

Conclusion

At Titantrek, quality and durability are at the heart of everything we create. From carefully chosen materials to automated assembly processes and rigorous testing, every step is designed to ensure our gear performs under the toughest conditions. Our vacuum compression system, for instance, makes packing easier without compromising strength or reliability.

"Crafted with rugged materials to withstand every adventure." - Titantrek[1]

This quote perfectly sums up our philosophy. A shining example of this is the Atlas Vault Backpack, introduced in April 2025. Its cutting-edge compression technology has become a game-changer for travelers, especially those dealing with bulky winter clothing or outdoor gear. Every feature is designed to address the practical needs of real-world travelers.

FAQs

How does the vacuum compression system in the Atlas Vault Backpack make packing easier for travelers?

The Atlas Vault Backpack features a vacuum compression system that makes packing easier and more efficient. By compressing clothing and other soft items, it helps cut down on bulk, giving you extra space for all your travel must-haves.

This is a game-changer for travelers who need to make the most of limited space while staying organized. Whether you're gearing up for a quick weekend getaway or a longer adventure, this system lets you pack more without the chaos of an overstuffed bag.

How does Titantrek test its products to ensure they are durable and weather-resistant?

Titantrek puts its travel gear through some of the toughest tests to ensure it holds up in real-world conditions. Every product faces rigorous stress testing to confirm it can handle the demands of heavy travel. For example, their waterproofing tests involve exposing gear to water in various scenarios to ensure it stays dry. They also conduct temperature resistance tests to verify performance in extreme hot or cold climates.

Beyond that, the materials are evaluated for tear resistance and durability over time, ensuring they remain reliable even with regular use. These meticulous testing processes are what make Titantrek gear dependable for adventurers tackling challenging environments.

How does Titantrek use customer feedback to improve its travel gear?

At Titantrek, we place a high value on customer feedback - it’s at the heart of how we design and improve our travel gear. By listening closely to what users share about their experiences, we fine-tune our products to meet the needs of today’s adventurers.

Whether it’s making our gear more comfortable with better ergonomic designs or boosting waterproofing and durability, feedback drives every improvement. From adjusting materials to introducing new features, our goal is simple: to create gear that stands up to the demands of real-world travel.

Reasons Why Titantrek is the Best Backpack Investment for Frequent Flyers

Titantrek vs. Traditional Backpacks: Is Upgrading Worth It?